Cargo Vessel Types

1) General Cargo Ship

A general cargo ship is a type of merchant vessel designed to transport various types of cargo, including packaged goods, dry bulk, and project cargo. These ships are versatile and can accommodate a wide range of cargoes, making them ideal for transporting different types of goods in a single voyage. They are equipped with cargo handling equipment and are manned by experienced crews to ensure the safe and efficient loading, transportation, and unloading of diverse cargoes across global trade routes.

2) Container Ships

A container ship is a specialized type of cargo ship designed to carry standardized cargo containers, facilitating efficient and secure transportation of goods worldwide. These containers come in standardized sizes, typically 20 feet or 40 feet in length, and are easily transferable between ships, trucks, and trains without the need to unload the cargo inside.

These vessels are designed to fit through the Panama Canal, with maximum dimensions of approximately 294 meters (965 feet) in length, 32.3 meters (106 feet) in width, and a draft of around 12 meters (39 feet).

Larger than Panamax ships, these vessels are built to operate on routes that do not require them to pass through the Panama Canal. They have dimensions exceeding the limits of the canal and offer greater cargo-carrying capacity.

These ships are designed to fit through the expanded locks of the Panama Canal, known as the New Panamax locks. They have increased capacity compared to traditional Panamax vessels and can carry more containers.

These are among the largest container ships globally, capable of carrying well over 20,000 TEUs (Twenty-foot Equivalent Units). They are specifically designed to handle massive volumes of cargo efficiently and are typically used for high-traffic shipping routes.

Feeder ships are smaller container vessels used to transport containers from smaller ports to larger hub ports, where they are then loaded onto larger mainline vessels for long-distance transportation.

Container ships play a crucial role in modern global trade, offering a cost-effective and standardized means of transporting goods across continents and facilitating international commerce on a massive scale.

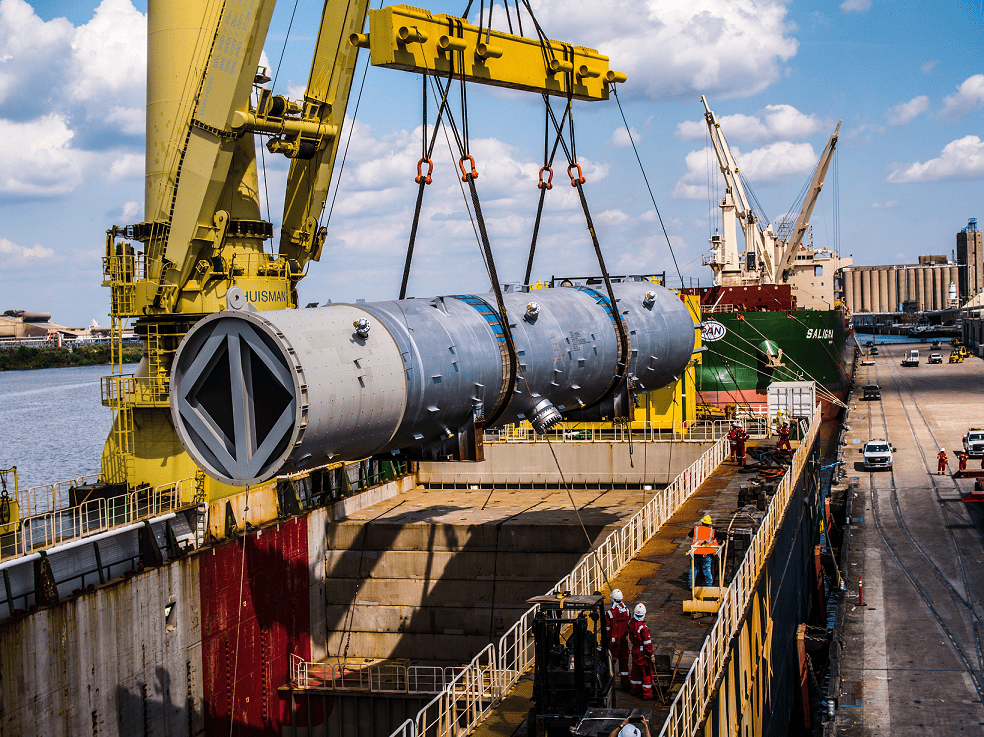

3) Heavy Lift Ships

Heavy lift ships are specialized vessels designed to transport heavy and oversized cargoes that cannot be accommodated by standard cargo ships. These ships have the capability to handle and lift extremely heavy loads, making them essential for industries such as construction, oil and gas, and infrastructure development. They are equipped with heavy lifting gear, such as cranes, and offer various features depending on the type of heavy cargo they are designed to carry.

Project cargo ships are specifically designed to transport oversized and heavy cargoes that cannot fit into standard containers or on regular cargo decks. These vessels have large open cargo holds and versatile lifting capabilities, allowing them to carry items like machinery, construction equipment, power plant components, and other project-related cargoes. Project cargo ships are ideal for handling unique, irregularly shaped, and challenging loads.

Open deck cargo ships, also known as open hatch ships, have open cargo holds with no fixed roofs or hatches. This design allows them to accommodate oversized and tall cargoes that would not fit into standard enclosed holds. These vessels are suitable for transporting items like wind turbine blades, large industrial components, and other lengthy cargoes that require an unobstructed deck space.

Dock ships are designed with a unique capability to submerge their deck to facilitate the loading and unloading of heavy cargo. They have a watertight dock or well deck that can be flooded, allowing cargo to be floated on or off the ship using tugboats or other specialized equipment. Dock ships are commonly used for transporting heavy equipment like oil rig modules, barges, and other items that need to be floated into position for loading or unloading.

Semi-submersible ships, also known as heavy transport vessels (HTVs), can partially submerge themselves by ballasting their hulls. This feature allows them to float lower in the water, creating a submerged deck capable of carrying heavy and oversized cargo. Once the cargo is loaded, the ship de-ballasts to raise the deck and become fully operational for transit. Semi-submersible ships are often used for transporting large offshore structures, drilling rigs, and other massive cargoes that cannot be easily loaded using traditional methods.

Overall, heavy lift ships play a crucial role in the transportation of extraordinary cargoes that require specialized vessels and equipment. Their ability to handle these heavy loads efficiently ensures the smooth execution of complex projects and contributes significantly to various industries’ success.

4) Oil Tankers

An oil tanker ship, also known as a petroleum tanker, is a specialized vessel designed for the transportation of liquid petroleum products such as crude oil, refined petroleum products, and liquefied natural gas (LNG). These ships play a critical role in the global energy industry, facilitating the movement of vast quantities of oil and gas from production regions to refineries and consumer markets around the world.

Crude oil tankers are designed to transport unrefined crude oil from oil-producing regions to refineries for processing. They come in various sizes and classes, ranging from small coastal tankers to massive Very Large Crude Carriers (VLCCs) and Ultra Large Crude Carriers (ULCCs). Crude oil tankers have dedicated cargo holds and tanks for carrying different grades and types of crude oil.

Product tankers, also known as refined product tankers, are designed to transport refined petroleum products such as gasoline, diesel, jet fuel, and other petrochemical products. These tankers come in different sizes, including Medium Range (MR), Long Range (LR), and Panamax vessels. Product tankers have segregated tanks to carry multiple products simultaneously, ensuring the safe transportation of various petroleum derivatives.

Chemical tankers are specialized vessels designed to transport a wide range of chemicals, including hazardous and non-hazardous substances. These tankers are constructed with special coatings and tank configurations to prevent chemical reactions and ensure the safe handling and transportation of various liquid chemicals.

LNG carriers are designed to transport liquefied natural gas, which is supercooled to a liquid state for ease of transportation. These vessels have cryogenic tanks to keep the LNG at extremely low temperatures to maintain its liquid form during transit. LNG carriers come in different sizes, including small-scale LNG carriers for regional distribution and large-scale vessels for long-distance transportation.

Capacities of Oil Tanker Ships:

The capacity of oil tanker ships is measured in Deadweight Tonnage (DWT) or Gross Tonnage (GT). DWT refers to the total weight of cargo, fuel, ballast water, provisions, and crew that a vessel can carry, while GT represents the total enclosed space within a ship. The following are the approximate capacity ranges for different types of oil tankers:

1) Small Coastal Tankers: 1,000 to 10,000 DWT

2) Medium Range (MR) Product Tankers: 25,000 to 50,000 DWT

3) Long Range (LR) Product Tankers: 50,000 to 80,000 DWT

4) Panamax Product Tankers: 60,000 to 80,000 DWT

5) Aframax Crude Oil Tankers: 80,000 to 120,000 DWT

6) Suezmax Crude Oil Tankers: 120,000 to 200,000 DWT

7) Very Large Crude Carriers (VLCCs): 200,000 to 320,000 DWT

8) Ultra Large Crude Carriers (ULCCs): 320,000 to 550,000+ DWT

9) LNG Carriers: Varies from small-scale LNG carriers (1,000 to 30,000 DWT) to large-scale vessels (up to 266,000 DWT or more.

It’s important to note that capacities can vary based on vessel design, modifications, and regulatory restrictions. These capacities give an overview of the general ranges for each type of oil tanker.

5) RORO

A Roll-on/Roll-off (RoRo) cargo ship is a specialized vessel designed for the transportation of wheeled and self-propelled vehicles, as well as other types of cargo that can be rolled on and off the ship. RoRo ships have large open decks and ramps that allow vehicles and equipment to be driven directly onto the vessel for loading and unloading, simplifying the cargo handling process.

Pure Car Carriers are RoRo vessels designed primarily for the transportation of automobiles. They have multiple decks to accommodate cars, trucks, and other light vehicles, with specialized arrangements to maximize the number of vehicles that can be transported safely and efficiently.

Pure Car and Truck Carriers are similar to PCCs but have the added capability of carrying trucks and other larger vehicles in addition to cars. These ships have adjustable decks and sometimes movable ramps to accommodate various vehicle sizes and configurations.

ConRo ships, short for Container-RoRo ships, are hybrid vessels designed to carry both containers and RoRo cargo. They have a combination of containerized cargo holds and RoRo decks, providing flexibility in transporting a mix of rolling and non-rolling cargo.

Though not purely RoRo vessels, Lift-on/Lift-off (LoLo) ships have a limited RoRo capability. They are equipped with onboard cranes to lift non-wheeled heavy cargo, such as construction machinery and project cargo, onto the vessel for transport.

Capacities of RoRo Cargo Ships:

The capacity of RoRo cargo ships is measured in terms of the number of standard car units (SCUs) they can carry or the lane meters of cargo space available on their decks. Lane meters represent the length of cargo lanes on the ship’s deck, typically measured in meters, where vehicles and cargo are positioned side by side.

RoRo ships come in various sizes, and their capacities can range from a few hundred to several thousand SCUs or lane meters. For example:

- Small RoRo ships: 1,000 to 5,000 lane meters or SCUs

- Medium RoRo ships: 5,000 to 10,000 lane meters or SCUs

- Large RoRo ships: 10,000 to 25,000+ lane meters or SCUs

The actual capacity can vary based on the ship’s design, deck configuration, and whether it is a dedicated RoRo vessel or a hybrid RoRo/Container carrier. Additionally, some RoRo ships have adjustable decks that allow for more flexible space utilization based on the cargo being transported.

6) Bulk Carrier

A bulk carrier ship is a specialized vessel designed for the transportation of dry bulk cargoes, such as coal, iron ore, grain, cement, and other similar materials. These cargoes are typically loose and not containerized, so bulk carriers have large cargo holds without any partitions to accommodate the bulk commodities efficiently. Bulk carriers are crucial in the global shipping industry, as they facilitate the movement of large quantities of essential raw materials and commodities.

Handysize bulk carriers are the smallest class of bulk carriers and are typically used for carrying cargoes to smaller ports and terminals with restrictions on vessel size. They have a capacity of around 10,000 to 35,000 deadweight tons (DWT) and are designed to navigate shallow and narrow waterways.

Supramax bulk carriers are larger than Handysize vessels and have a capacity of approximately 35,000 to 60,000 DWT. They offer more efficient cargo handling capabilities and are versatile enough to call at a wide range of ports and terminals.

Panamax bulk carriers derive their name from their size, as they are designed to fit through the original locks of the Panama Canal. These vessels typically have a capacity of about 60,000 to 80,000 DWT and can carry cargoes to ports with restrictions on vessel size.

Capesize bulk carriers are among the largest bulk carriers and cannot fit through the Panama Canal. They have a capacity of approximately 100,000 to 200,000 DWT or more. Capesize vessels are often used for long-haul transportation of iron ore and coal, primarily on routes between major bulk commodity producing countries and consuming regions.

VLOC and ULOC are specialized types of bulk carriers designed specifically for the transportation of large quantities of iron ore. VLOCs typically have a capacity of over 200,000 DWT, while ULOCs can exceed 300,000 DWT.

Capacities of Bulk Carrier Ships:

Bulk carrier capacities are measured in deadweight tons (DWT), which refers to the total weight of cargo, fuel, ballast water, provisions, and crew that a vessel can carry. The capacities of bulk carriers can range from a few thousand DWT for Handysize vessels to well over 300,000 DWT for the largest Capesize and ULOC ships. To give an overview of their capacities:

- Handysize Bulk Carriers: 10,000 to 35,000 DWT

- Supramax Bulk Carriers: 35,000 to 60,000 DWT

- Panamax Bulk Carriers: 60,000 to 80,000 DWT

- Capesize Bulk Carriers: 100,000 to 200,000 DWT

- VLOC and ULOC: Over 200,000 DWT, with ULOCs exceeding 300,000 DWT

The choice of bulk carrier type depends on the specific cargo requirements, port capabilities, and trade routes involved in the transportation of dry bulk commodities.